NEWS

The Story Behind: The Hummingbird Notebook

BECOME A FLEMING INSIDER > JOIN HERE

The Story Behind: The Hummingbird Notebook

Posted on 3 March, 2025

Ever wanted to see a book being made? Come with us into the English binding workshop of the Stamford Notebook Company, to watch our Hummingbird Notebooks being made. Let’s go.

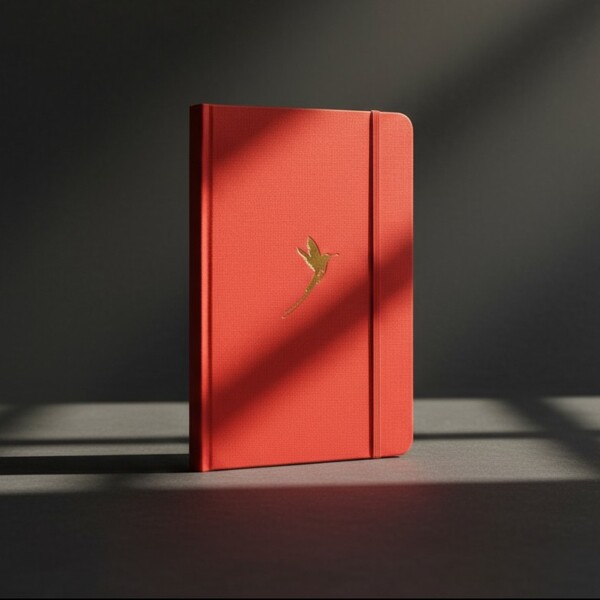

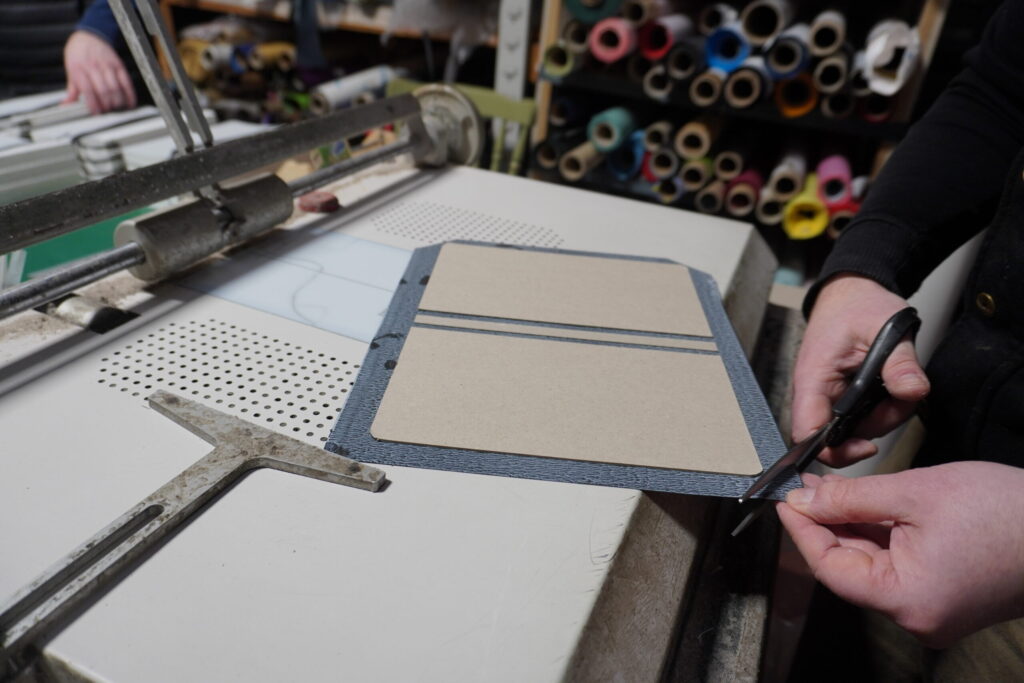

Soft leather or buckram fabric is selected for the cover – we offer a choice of two finishes. Cardboard panels are glued to the cover material, then trimmed, folded and carefully smoothed out. Custom metal dies and gold foiling are then used to blind emboss and hot foil emboss the hummingbird into the front cover. Slits are made in the back cover to allow elastic to be inserted, trimmed and glued in place.

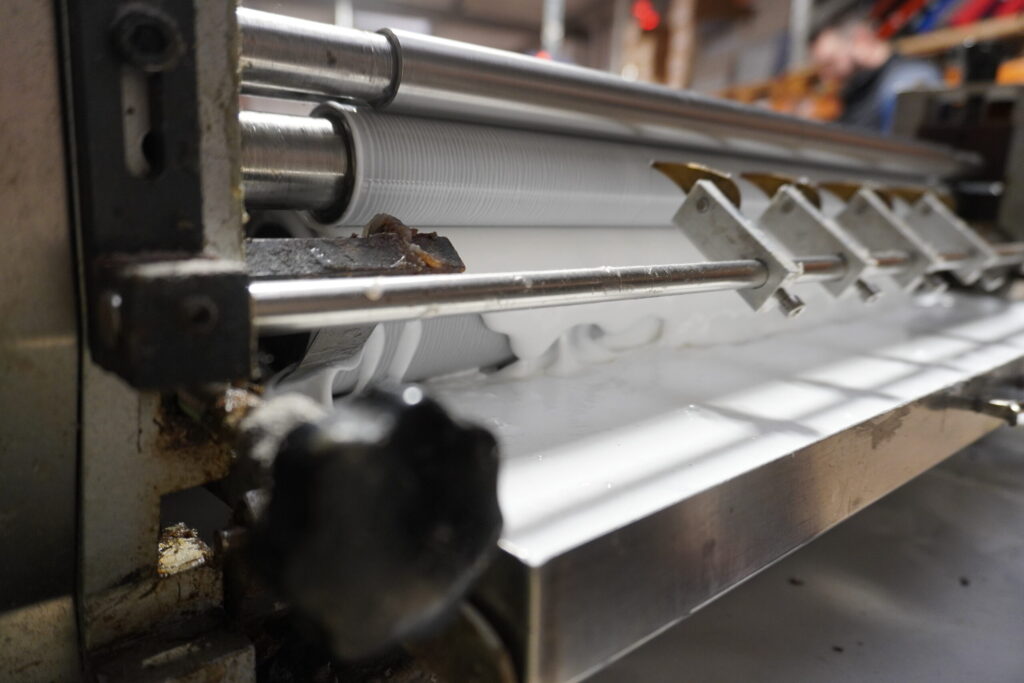

The notebook pages are printed in-house using British made, fountain-pen friendly paper milled in the Cumbrian town of Kendal.

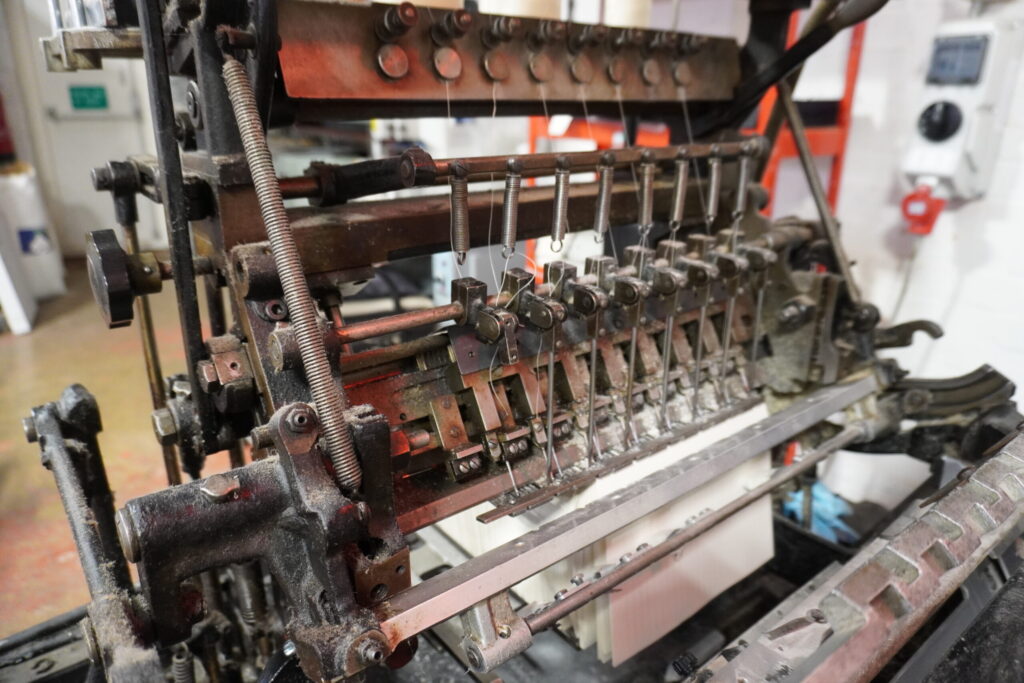

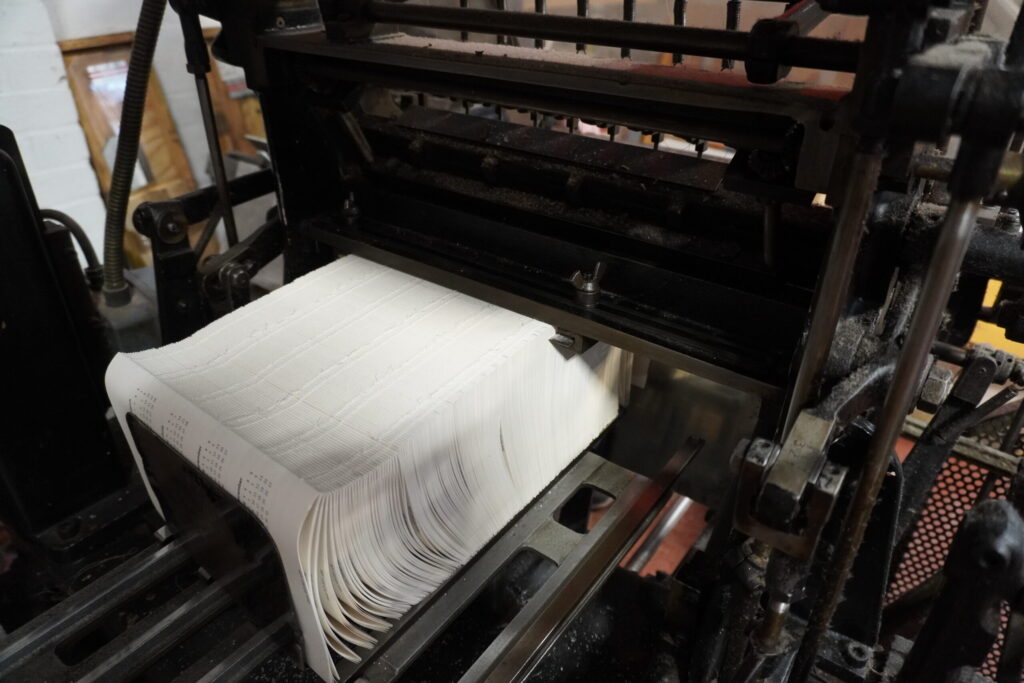

Groups of printed sheets folded in the middle, called sections, are sewn together by a 1948 Smyth book sewer, which allows the book to open fully whilst remaining very strong. A piece of reinforcing paper is glued over the sewn sections, securing the endpapers in place. The pages are trimmed – first around each edge, and then the corners are rounded.

A bookmark ribbon is glued to the spine of the pages and trimmed. The book is then cased-in – the first and last pages are coated in glue, and the cover is attached.

The notebooks are sandwiched between sheets of protective cardboard, and then pressed in a hand-operated press to help seal the glue. As a finishing touch, they are then pressed in a separate machine to produce an indent along the spine – the French Groove – which allows the book to open flat.

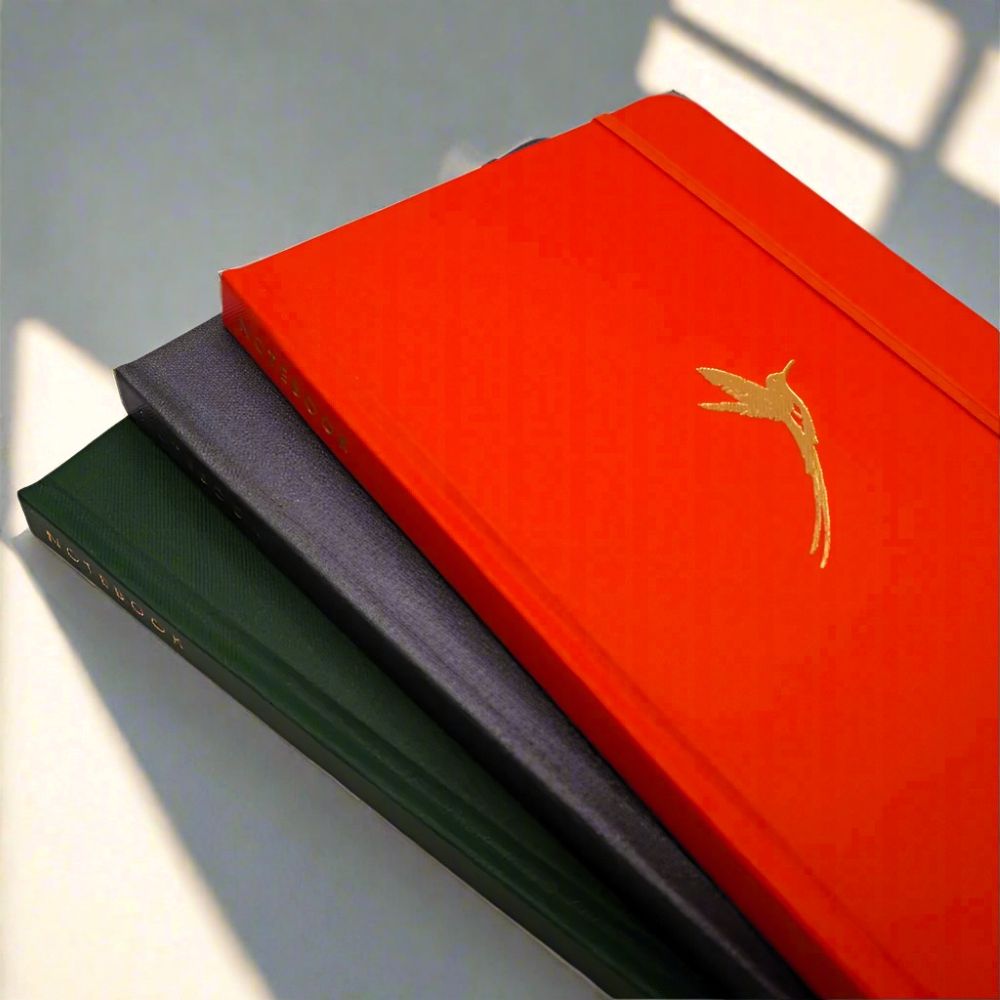

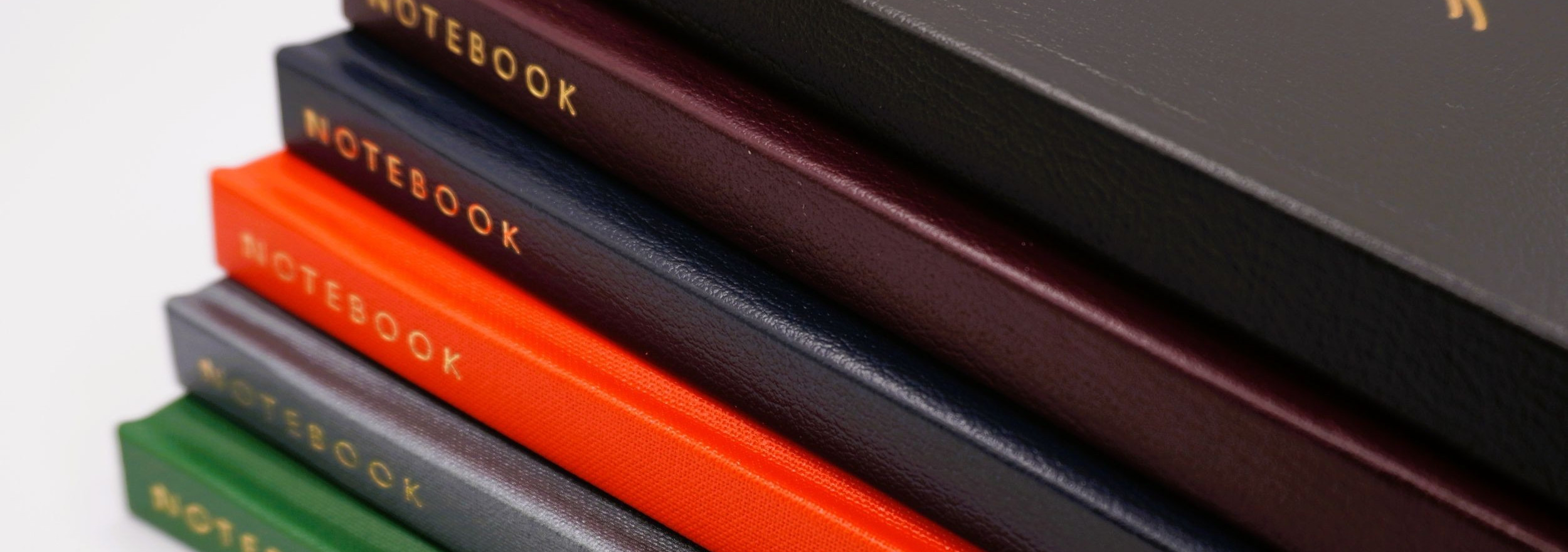

The Hummingbird Notebook is available exclusively from our shop here in a range of colours and cover finishes.